What is a fulfillment center?

Fulfillment Center Definition: While the actual fulfillment in logistics means the assumption of tasks for order processing, the term “fulfillment center” refers to the place of processing.

Many different logistics processes are handled in a fulfillment center. Customer orders are received, processed, packed and dispatched. It is an important strategic point within the supply chain and enables greater efficiency with a fast flow of goods.

It is a specialized warehouse that focuses on fulfilling the entire order processing for merchants and online retailers in e-commerce, but also for retailers.

It offers comprehensive services such as storage, packaging and shipping of products to end customers. By outsourcing these tasks to an external fulfillment center, entrepreneurs can save time and resources. Concentrate more on your own core business and reduce fixed costs.

The centers ensure efficient and reliable processing of incoming orders, which leads to improved customer satisfaction and efficient sales processes.

How does a fulfillment center work?

The Fulfillment Center is connected to the online store, ERP or Wawi system via an interface. The automated retrieval of customer orders then takes place for order processing and delivery to the customer.

By taking over these order fulfillment processes, companies are relieved of many tasks.

Orders are assembled, packed and dispatched by warehouse staff or, with increasing automation, by robots.

The center is equipped with a variety of technologies that enable orders to be processed smoothly. These include barcode scanners, automatic sorting systems and warehouse management software.

Fulfillment centers typically offer after-sales services such as inventory management, returns processing, item reconditioning and customer support.

Benefit from the advantages of a fulfillment center

The advantages of a fulfillment center in logistics are obvious! Solutions are offered here, such as the central storage of goods with order picking and dispatch to the end customer.

- On the one hand, retailers can save time and resources as they do not have to worry about fulfillment tasks such as storage, shipping, returns or refurbishment of their products when outsourcing.

- Instead, retailers can concentrate on growing their business. On the other hand, they can benefit from the technology with automated processes and the expertise of the logistics service providers. This allows orders to be processed more efficiently.

- In addition, retailers can work in a scalable manner because large quantities of products can be processed. This is particularly important on promotional days such as Cyber Monday or Christmas.

- This solution enables companies to reduce their operating costs as they do not have to provide their own warehouses, infrastructure and employees. A logistics center also facilitates access to global markets.

By outsourcing fulfillment tasks, online retailers can once again focus on their own core business.

Different types of center bearings

Not every fulfillment center is the same. There are different types of warehouse that specialize in different warehousing and order processing.

Some, for example, only offer pallet storage and shipping, while other centers also offer picking, packing and returns management.

There are also specialized distribution centers that focus only on certain industries or products, such as food, animal feed, hazardous materials, building materials or fashion.

What is a distribution center?

A distribution center is a warehouse that serves as a hub between the manufacturer, a supplier and the end customer. Its purpose is to store large quantities of goods and distribute them to different locations or customers.

In this way, companies can reduce transportation costs by storing large quantities of goods at a central location and distributing them from there. Especially if the goods are to be imported from abroad and sold within the EU.

A distribution center can also help to optimize stock levels by acting as a buffer zone within the supply chain between production and sales, thus reducing stock levels on the sales floor or in stores.

What is a pallet warehouse?

There are warehouses that can store pallets in high racks. This is particularly cost-effective if many single-variety pallets are stored and simply sent back to another center or wholesaler as required.

What is a small parts warehouse?

In a small parts warehouse, items are stored in shelving racks. This is helpful if several small items have to be picked for one order.

This involves either dynamic picking (goods to the packer) or the software on the handheld shows the order picker in the warehouse the sequence and number of items to be packed for an order.

But this type of storage is also very effective for parcels with individual packaging, gift packaging and sensitive products.

What does a fulfillment center cost?

Various costs may be incurred in the fulfillment center, which vary depending on the services and the scope of processing. Here are some costs that are typically incurred in the fulfillment center:

- Storage costs: This includes rental or lease costs for the storage space, operating costs such as electricity and water as well as insurance for the warehouse. The required storage space is calculated by cubic meter storage price or by meter per shelf rack.

- Personnel: Costs for employees involved in order processing.

- Technology and equipment: Expenses for warehouse management systems, barcode scanners, packaging materials, floor vehicles, stretch machines and other necessary equipment.

- Shipping costs: Costs for shipping the products to customers, which may vary depending on the shipping method, size and weight of the packages.

- Returns: Costs associated with returns of products by customers, including storage, inspection, reconditioning or disposal of returned goods.

- Technology and software licenses: Expenses for the use of inventory management software, order processing systems and other technological solutions.

- Additional service: Costs for additional services such as customized packaging, gift wrapping, personalized notes, packaging of goods, special preparation of goods or refurbishment of products.

The exact costs vary depending on the scope of services, the size of the fulfillment center, the number of orders processed and the specific requirements of the company or customer.

Fulfillment center for marketplaces

Amazon’s fulfillment centers, for example, are specially designed for order processing by Amazon sellers. Amazon retailers can also use external logistics centers and have the goods professionally delivered in partial quantities to the desired Amazon fulfillment center. This process is also called pre FBA service.

There are also fulfillment centers for online retailers such as Otto or eBay, which store the goods and ship them to customers once the order has been received.

While Amazon operates its own fulfillment centers, Otto uses the services of Hermes Fulfillment and eBay uses the Asian provider Orange Connex.

It is important to choose the right fulfillment center for your needs to ensure that your orders are processed quickly and efficiently.

Choosing the right fulfillment center

To choose the right fulfillment center, you should first identify your specific needs and requirements.

Think about what service you need, how quickly your orders need to be processed and what type of products you want to ship.

Compare the offers and costs of different providers and check their experience and reputation.

It can also be helpful to ask for references from other customers and find out about the logistics center’s technology and systems to ensure that they meet your requirements.

If possible, you should view the storage area on site, take product samples with you and discuss the project with those responsible.

Check beforehand whether you can connect your online store, ERP or Wawi system to the fulfillment center. Are separate fees charged for setting up the interface?

Which processes are handled automatically by the software? Does the Fulfillment Center take over the inventory management of the items in your store? Is the status updated in the store?

Also clarify in advance whether you will be assigned a direct contact person. Are fees charged for support? Does the company work with a ticket system or can you call quickly and clarify everything?

How fast are the delivery times and which shipping service providers does the logistics center work with?

Depending on the products you sell, it is important to use the right shipping service provider.

While UPS is often used in the B2B sector, many online retailers often use DHL for reliable shipping.

DPD offers good conditions for somewhat heavier products. If you would like to send small goods nationally or internationally, delivery by Warenpost is a fast and inexpensive option.

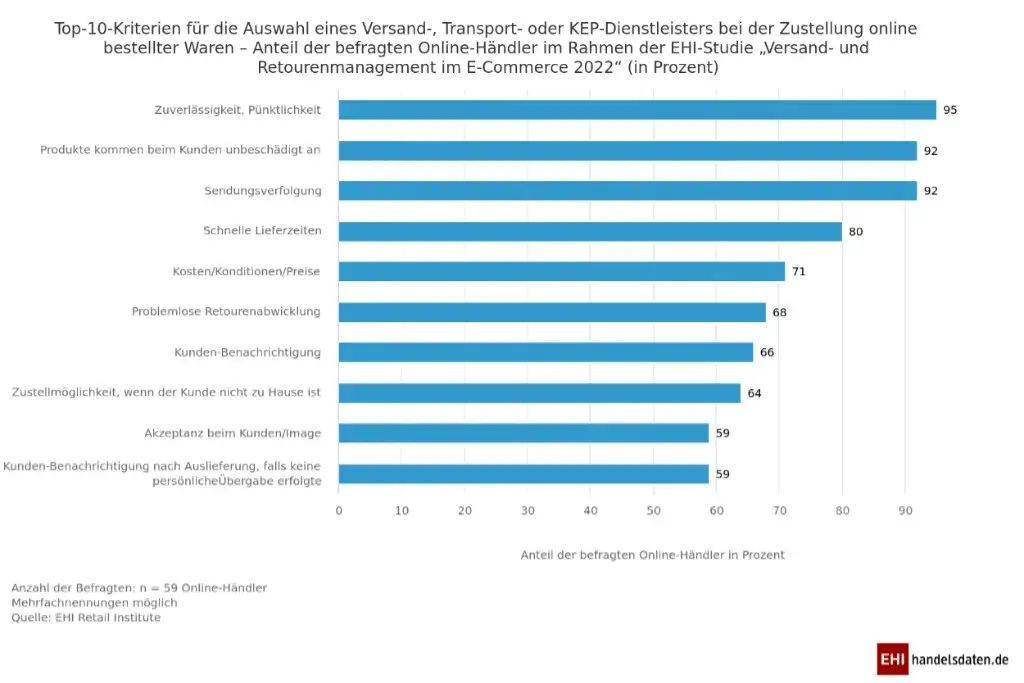

Top 10 criteria for selecting a shipping, transport or CEP service provider

Source EHI Retail Institute. This chart shows the results of the survey of online retailers as part of the EHI study “Shipping and returns management in e-commerce 2022 ➚“. Respondents were asked about the most important criteria for selecting a shipping, transport or CEP service provider for the delivery of goods ordered online. When choosing a shipping service provider, 95 percent of respondents cited reliability and punctuality as decisive criteria.

The location of a fulfillment center: an important strategic factor!

When choosing a location for a fulfillment center, proximity to the target market is a decisive factor.

The closer the center is to the target market, the faster the orders can be delivered and the lower the shipping costs.

Another important factor is the proximity to important transportation routes such as freeways, airports or ports to ensure fast and efficient delivery.

The Port of Hamburg, for example, offers many locational advantages. Goods from all over the world are delivered there every day. China wants to operate its own terminal in the Port of Hamburg with the Cosco shipping company.

Hamburg is already 100 km inland from Germany. Once the containers have been unloaded from the ship, they can be taken to a logistics center near Hamburg on the same day.

The goods ordered by the customer can then be delivered anywhere in Germany within one day.

In addition to the strategic location, the size of the center is also an important factor. It is important that the logistics center is large enough to store sufficient stock and ensure that orders are processed quickly.

At the same time, the operating costs of the warehouse should not be too high in order to ensure profitable operation.

Very large centers with robot technology are extremely cost-intensive. In order for the operating costs to be profitable, a large number of parcels must be processed in a short time. Therefore, such large and modern fulfillment centers are only suitable for retailers who have monthly parcel shipments of over 10,000 items.

- E-Commerce Fulfillment

- Fulfillment for wholesalers

- Fulfillment for marketplaces

- Cross-Docking

- Transshipment warehouse

- Deliveries to B2C, B2B and D2C

FAQ - Fulfillment Center

- Was ist ein KEP-Dienstleister?

Ein KEP-Dienstleister ist ein Unternehmen, das Kurier-, Express- und Paketdienste anbietet. "KEP" steht dabei für Kurier, Express, Paket. Diese Dienstleister sind darauf spezialisiert, Pakete, Dokumente oder Sendungen schnell und zuverlässig von einem Ort zum anderen zu transportieren.

- Was bedeutet Auftragsabwicklung im Fulfillment?

Die Auftragsabwicklung im Fulfillment bezieht sich auf den Prozess, bei dem ein Unternehmen Bestellungen von Kunden entgegennimmt, bearbeitet, verpackt und versendet. Es umfasst sämtliche Schritte von dem Zeitpunkt an, an dem eine Bestellung eingegangen ist, bis hin zur Auslieferung an den Kunden.